The Statement of Manufacture:

A signature to go with every appliance supplied by a Laboratory that says it has been manufactured to the standards and guidelines set out by the MHRA.

– Who can sign it?

In 2008 statutory registration was forced upon Dental Technicians by, and overseen by, the General Dental Council.

A good idea in a couple of areas maybe, for example keeping any ‘cowboys’ out of the trade or at least making them ‘come up to scratch.’ Part of this entails ‘Continuing professional development’ by spending our own time and money on often meaningless hours of study to be able to stay registered.

So at the very least this should mean something, something like giving the signing of the SoM some worth. Not necessarily according to the GDC or the MHRA.

So then I read the next three paragraphs in the July issue of ‘The Dental Technician’

A Dental Technician (not me though I wish I had thought of it) has asked the GDC and the MHRA if there are any restrictions as to who can sign the SoM.

The MHRA said “In terms of the Medical Devices Directives (93/42/EEC), there’s no specific stipulation that the statement of manufacture must be signed off by someone suitably qualified or by a GDC registrant”

The GDC was asked “If there is any legal bar that they are aware of that prevents anyone from signing the SoM? The GDC replied “This is a legal matter on which the GDC cannot advise. You may wish to seek legal advice on this matter”

So even work from abroad, (some good, some bad) does not have to be checked by, adjusted if necessary, and signed off by a Technician who would be struck off if not registered with the GDC and signed up with the MHRA. The same GDC by the way who are proactive in hunting down any Technician for the slightest misdemeanour and fining or banning them.

Conclusion:

The GDC is an Ass.

Until next time…….

To scan, or not to scan, that is the question— Whether ’tis nobler in the mind to wax up, invest, cast, sandblast, seat down, trim and prepare for opaque-

The Copings and Bridges of outrageous fortune,

Or to take arms against a sea of troubles,

By scanning, drop boxing, receiving in the post, end them? To die, to sleep—no more; and by a sleep, to say we end the heart-ache, and the thousand natural shocks that flesh is heir to!

Or a case of the Technician doth protest too much, methinks?

Or a case of the Technician doth protest too much, methinks?

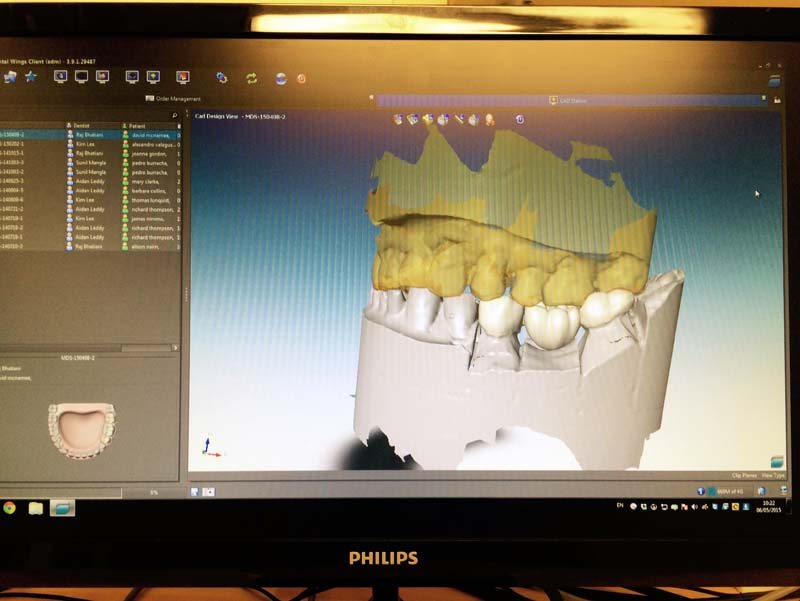

The purchase of a 3D dental scanner is a huge outlay for any Dental Lab, equivalent to buying 3 top end porcelain furnaces in one hit. How can a small to medium Laboratory afford to take such a financial risk? This abuser of Shakespeare’s great works says how can you not?

The Lost-wax technique, investment casting or cire perdue as those crazy French Techs call it, is not new. The oldest known examples of this technique are the objects discovered in the Cave of The Treasure hoard in southern Israel, which belong to the Chalcolithic period (4500–3500 BC) i.e. 5700 years old!

As a junior technician, the fit of copings after waxing up and casting was almost a lottery, often dependent on nonexistent aircon or central heating to maintain a mean temperature in the Lab that would enable a consistent fit. Yes, newer investments are more user friendly and produce excellent fits when the manufacturer’s instructions are followed to the letter, which is just as well as I still have to (for the moment) cast FGC’s.

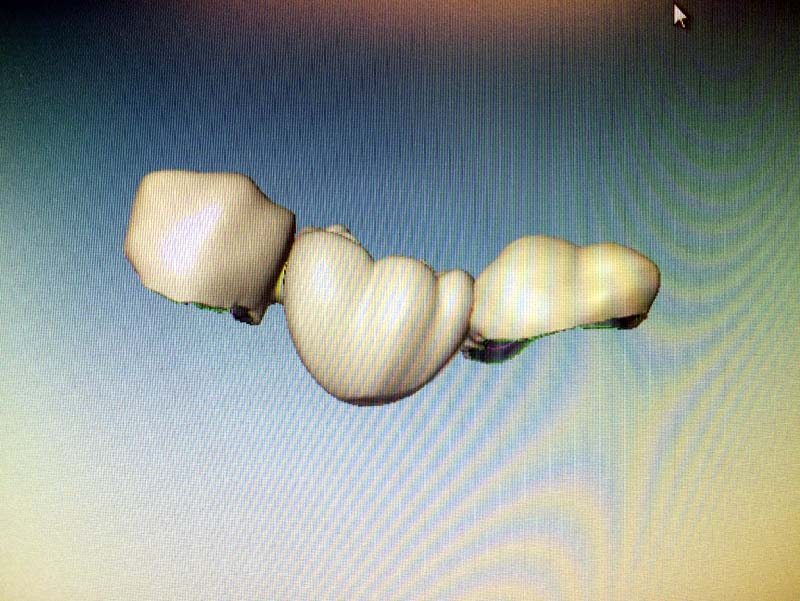

Thus far I have concentrated on the humble PBC coping, so here is a list of the usual’s that I scan and have milled or printed for me.

NP copings and frameworks to full arch,

NP copings and frameworks to full arch,

Implant abutments,

Screw down crowns and Bars Zirconia copings,

full crowns and frameworks to full arch

e.max copings and full crowns

Temporary crowns and bridges to full arch

Scan and 3d print denture

base plates and working models

Nothing (as they say) is perfect, (who the heck are they btw?) but it’s pretty bloomin close. A time and motion study (there’s one for the oldsters) would at the very least make you raise an eyebrow. Often of a morning I feel inclined to dislocate my right elbow and pat myself on the back for having taken the financial plunge. Next on the list, my own milling machine, equivalent to buying a Range Rover Evoque!!!!!!

Until next time………………………